Introduction

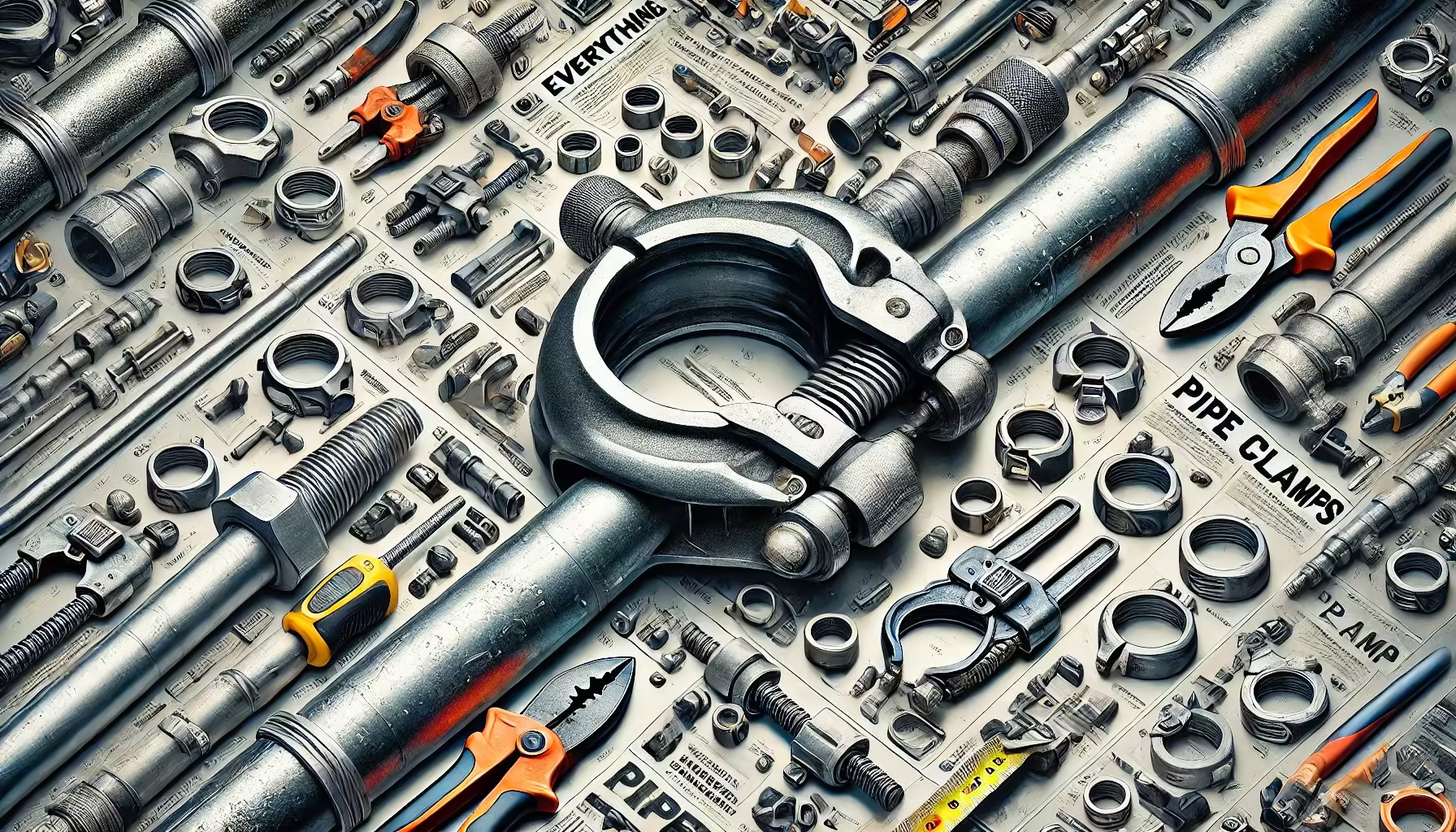

Pipes require secure, stable, and tight connection in several application fields, so pipe clamps are among the necessary tools in the plumbing, construction, automotive, and industrial sectors. Whether you’re a DIY fan or a professional contractor, being able to identify the different types of pipe clamps along with their applications can assist you in finding the perfect tool you need.

Let’s face it; the reality of not having such a clamp in the first place while preventing damage may cause injuries year after year. Pipe clamps are required!

What is a Pipe Clamp?

A pipe clamp is a tool used to hold or secure pipes, tubing, or other cylindrical objects securely in place. It is usually a band or bracket that you wrap around the pipe and then tighten to create a secure hold. Pipe clamps are made in different sizes, materials, and designs depending on the pipe type and the use to which it is for.

Types of Pipe Clamps

The fixed pipe clamp selection which will likely be the leading factor in the project’s success. Here are the most common types of pipe clamps available, each designed for specific purposes:

1. Standard Pipe Clamps

Standard pipe clamps, which are also known as U-bolt pipe clamps, are among the most commonly used components in plumbing and building construction. The purpose of the clamps is to hold everything in place either on walls, ceilings, or floors. The materials in general are mostly aluminum and the quires that are used to make them are smaller in size and are first joined together with a harness that is bolted to a wall along with the rear plate. These clamps are typically made from metal and have a U-shaped bracket that fits around the pipe, while the ends of the bracket bolt into a surface.

- Common Uses: Plumbing installations, HVAC systems, and securing pipes in industrial settings.

2. Saddle Pipe Clamps

Saddle clamps are designed to prevent pipes from running horizontally. They have a saddle-shaped bracket that holds the pipe so that it does not move and the pipe remains in the place where it should be. This supports the utility of securing pipes to flat surfaces and beams. Saddle clamps are ideal for securing pipes to flat surfaces or beams.

- Common Uses: Securing horizontal pipes in plumbing systems and industrial applications.

3. Hinged Pipe Clamps

Hinged pipe clamps can be installed and removed easily thanks to their hinged design. These are the best solution to several issues such as when one has to fix a pipe in tight spaces or when there are so many pipe installations and removals. Hinged pipe clamps are available in different materials, like steel, aluminum, and plastic.

- Common Uses: Plumbing repairs, automotive applications, and quick installations.

4. Split Pipe Clamps

Split clamps consist of two separate parts that are bolted together around the pipe. This design allows for easy installation and removal, making the split pipe clamps suitable for cases where the pipe is limited onsite or in case the pipe might need removing. They are often used in HVAC and plumbing systems.

- Common Uses: HVAC systems, plumbing installations, and supporting large pipes.

5. Cushioned Pipe Clamps

Cushioned pipe clamps are designed to reduce vibrations, noise, and wear on pipes. These clamps feature a rubber or plastic cushion that sits between the clamp and the pipe, providing insulation and protection. Cushioned clamps are commonly used in applications where pipes are prone to vibration, such as in automotive and industrial machinery.

- Common Uses: Automotive exhaust systems, mechanical equipment, and industrial piping.

6. Pipe Repair Clamps

Pipe repair clamps, as the name suggests, are designed to repair leaking or damaged pipes. These clamps are typically made from stainless steel and feature a rubber gasket that seals the leak when the clamp is tightened around the pipe. They are a quick and cost-effective solution for temporary pipe repairs.

- Common Uses: Emergency pipe repairs, temporary leak fixes in water and gas pipelines.

7. Beam or Strut Pipe Clamps

These clamps are used to attach pipes to steel beams or struts. They are commonly used in commercial and industrial settings where pipes need to be suspended from beams or other structural supports. Beam clamps come in various sizes to accommodate different pipe diameters and support loads.

- Common Uses: Commercial plumbing, industrial piping systems, and HVAC installations.

Common Uses for Pipe Clamps

Pipe clamps are a product that is utilized throughout many industries and everyday life. Here are some of the most common uses:

- Plumbing: Attaching water and gas pipes to residential, commercial, and industrial plumbing systems.

- Heating, Ventilation, and Air Conditioning Systems: Supporting air ducts and pipes in heating, ventilation, and air conditioning installations.

- Cars: Attaching exhaust pipes, fuel lines, and other tubing in vehicles.

- Industrial Machinery: Lessen the vibration and noise in fitter machine and recreation of particular mechanism work and machinery.

- Construction: Support the piping at building construction and infrastructure projects.

Conclusion:

Securing pipes in a residential plumbing system, working on an automotive exhaust system or installing industrial piping are all examples of situations among which choosing the right pipe clamp is imperative for the safety, performance, and longevity of each is the case. With the different types of clamps available there could be cushioned and split clamps to pipe repair clamps, it is important to choose the right clamp for the job.

Another thing that should be taken into consideration is the size, material, and application of the pipes when you are choosing a clamp. In doing so, you will achieve a secure fit and get the most out of your project. Take a look at our wide collection of pipe clamps and locate the ideal solution for your exigencies.!

For More: Top-Rated Mobile Car Detailing Near Me: We Bring the Shine to You!